A family-owned apple farm in the Upper Midwest is taking advantage of a change in the local zoning code that added a new Agri-Tourism class in the existing farm zone. This allows the Owner to build a new facility on their existing site. The building will be open to the public and include a brewery, distillery, tap room, and market. The architect is ready to submit the drawings to the Owner for the 50% construction documents review.

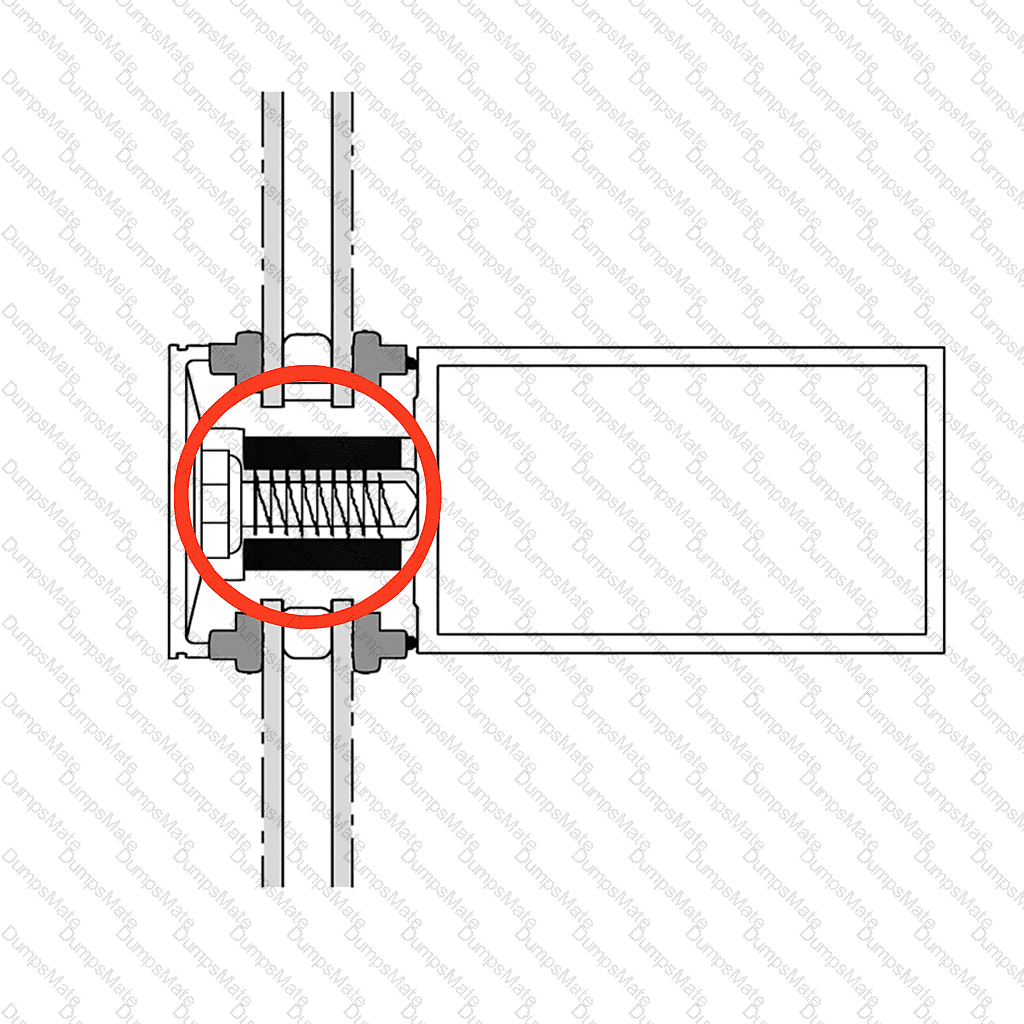

To accommodate a compressed construction schedule, the Owner will be utilizing a design-build process. The Contractor has submitted the Pre-Engineered Metal Building (PEMB) shop drawings to the Architect for review, due to the lead time on this critical path item. Once construction begins, farming operations must be able to continue uninterrupted.

Key project information includes:

Brewing and distilling will operate year-round.

Brewery will initially include four fermenting tanks. Owner has requested space for at least two additional tanks. Potential expansion will be based on future sales.

Distillery will produce 16% alcohol, which is classified as a flammable liquid. Fire separations are required.

Tap Room is designed with seating for 300 people, not including exterior patio seating. It will have views to the working orchards and the historic buildings on site.

Tap Room is scheduled to be open from August through November. Owner would like options to extend operating dates based on popularity.

The Market area will feature local farm products and is not conditioned.

Entire building will be fully sprinklered.

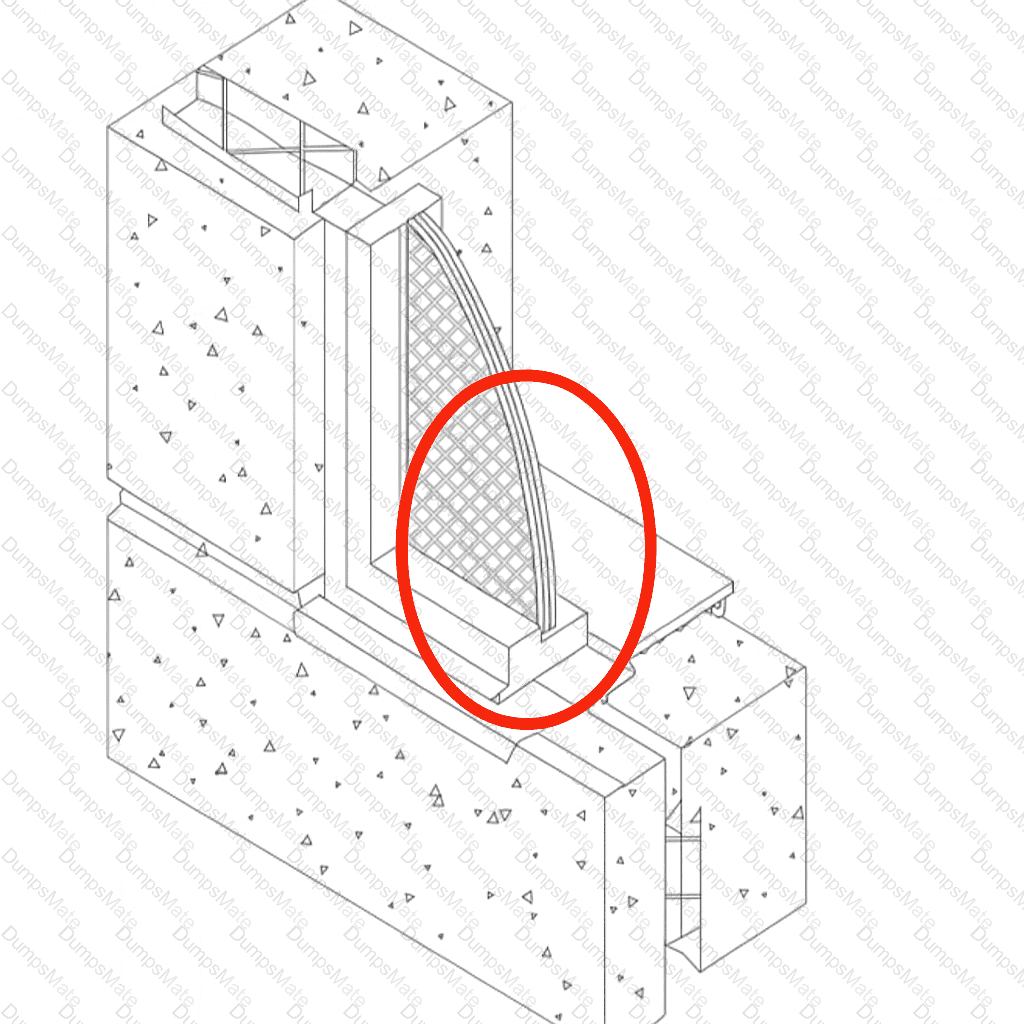

Selected building materials are low-maintenance, as requested by the Owner, for durability and to reflect the nature of a working farm.

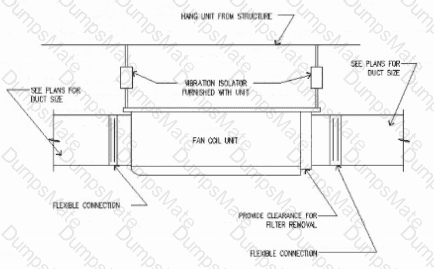

Mechanical and electrical systems will be hung from the building structure. These loads are included in PEMB shop drawings.

Public water and sewer is not available at the Project Site.

Occupancy sensors are included to reduce utility costs and achieve energy conservation requirements.

The following resources are available for your reference:

Architectural Drawings, including plans, elevations, sections, and schedules

Consultant Drawings, including structural, HVAC, power distribution, and plumbing

PEMB Shop Drawings

Design and Construction Schedule

Specification Excerpts, showing relevant spec sections

IBC and ADA Excerpts, showing relevant code and accessibility sections

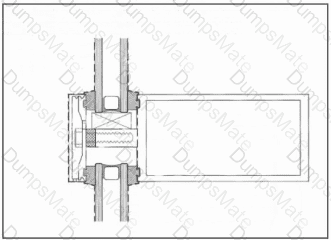

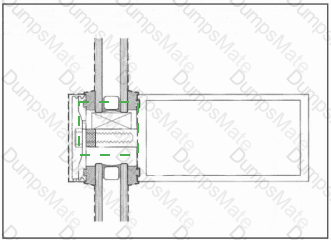

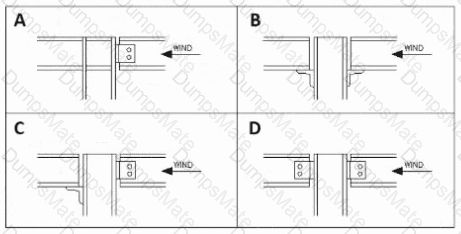

After reviewing the documents, the architect discovers a coordination issue in the corridor.

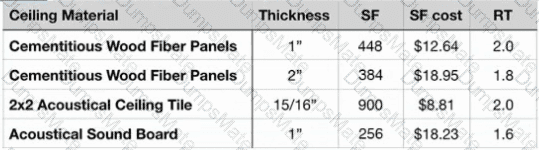

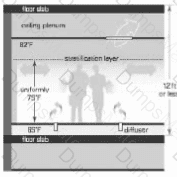

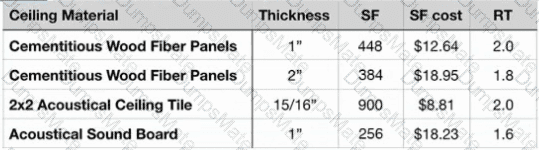

The owner is concerned about elevated noise levels in the Tap Room when fully occupied. The current design utilizes a 2 x 2 acoustic ceiling tile system installed above the fans. An acoustical engineer recommends noise mitigation through limiting reverberation time (RT) to 2.0 seconds or less in the space. This can be achieved by the provided ceiling material options and their corresponding area.

What should the architect recommend that will minimize additional project costs while providing the recommended acoustical solution?